Basic Parameters

Model | Prism XP100 |

Technology | TI DLP technology |

Forming Method | Top-down |

Resin | 405nm Resin, Ceramic Slurry |

Support Files | SLC PR3 |

Forming Size | 96*54*100mm / 120x70x100mm / 144x81x100mm |

Pixels Resolution | 50μm / 65um. / 75um |

Light Uniformity | >95% |

Layer Thickness | 0.02 – 0.1mm (Z axis Reposition Resolution 0.01mm) |

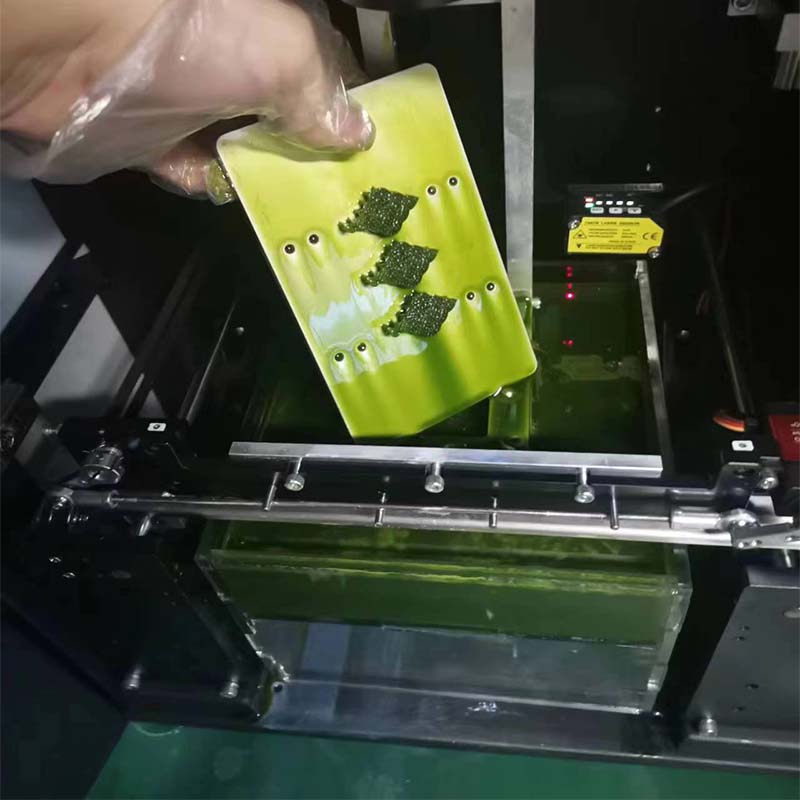

Printing Platform | Magnetic detachable platform |

Paving System | Adjustable negative pressure scraper |

Tank capacity | 1 liter (printing height 10mm) / 5 liters (printing height 100mm) |

Machine Size | 410x 340x650mm |

Weight | NW: 15KG GW: 40KG (including box) |

Print Way | off-print, or by USB |

Warranty | one year |

Competitive Advantage:

1. Suitable Projector modes: 405nm and 385nm.

2. For material testing, we created the unique testing function. No complex operations are required. It supports single-layer exposure of specified models. The parameters can be modified directly on the touch screen, and a set of curing parameters can be tested in one minute. Simple models can be printed with just a few milliliters to test the properties.

3. It supports SLC file, support multi-layer thick files. And data sliced by JewCad, Chitubox, Mange, Magics amd other softwares.

4. Scrapers: two kinds, vacuum adsorption scraper and up-and-down scraper. Printing models: support scraper mode and scraper-less mode for continuous molding.

5. The projector can move up and down on the track, and can modulate a variety of precision and printing formats as need, achieving an adjustment of 20%. Such as 50um 96x54mm printing format can adjust to 40um 73x43mm formats or 60um 115x64mm formats.

6. Equiped with various tanks with different sizes. Users can customize the tank.